Laser cutting

Craig Miller

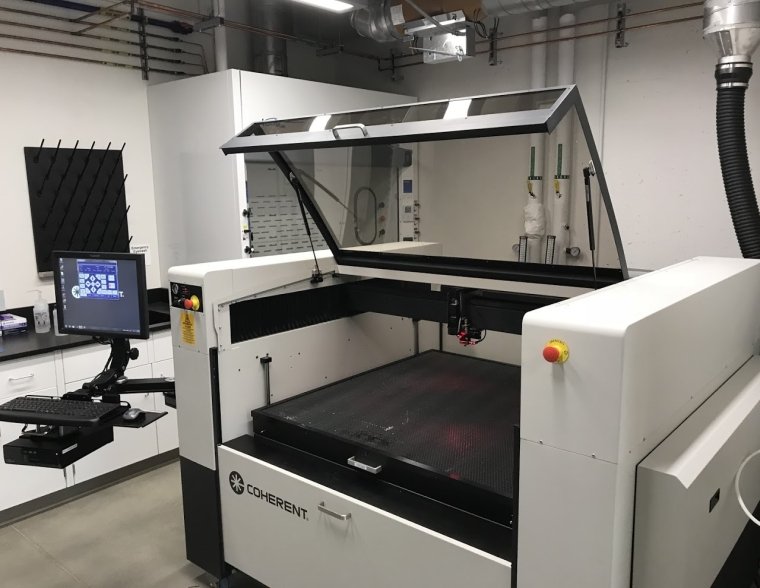

Coherent Meta 2C

The Coherent Meta2C is a 250 W laser that cuts and engraves quickly and easily on materials such as acrylic, paper, wood, and thin steel.

The laser cutter is mainly used for organic materials with 250 W of laser power at a wavelength of 10.6 micrometers.

This machine has a large cutting bed of 1.2 m x 1.2 m (4' x 4'), which is great for large projects or layout.

| Acceptable materials | Unacceptable materials |

|

|

Acrylic

Acrylic is probably the most commonly used material on the laser cutter, but there are a few things to keep in mind. Not all acrylic is equivalent, and some is really quite bad to cut. If possible, choose "cast" rather than "extruded" acrylic. Special acrylics can also have some additive that can be problematic. Acrylic sheets typically come with a protective material on both sides. If this is a plastic film, it has to be removed before cutting, and the surface of the acrylic is likely going to be somewhat damaged during cutting. If the material is paper, then it can be left on and the surface finish will be far better.

Etching

The laser cutter can also be used to etch various materials. It is particularly good at etching dark anodization off of aluminum panels. For example, if you are making an enclosure or a control panel, labels for switches, buttons, and indicators can be made using the etching feature.

Design requirements

Choosing the correct size material for a part can end up being a bit complicated in some cases. Please contact use for guidance if you are not sure. For example, the cutting "beam" lens has a focal length of either ~60 mm or 120 mm (depending on the situation, one of two different lenses can be used). The actual kerf generated by cutting depends on the thickness of the material and its composition.

Available to Yale researchers only